Supported by

Why concrete recycling?

Raw material shortage

Use of land

Emissions

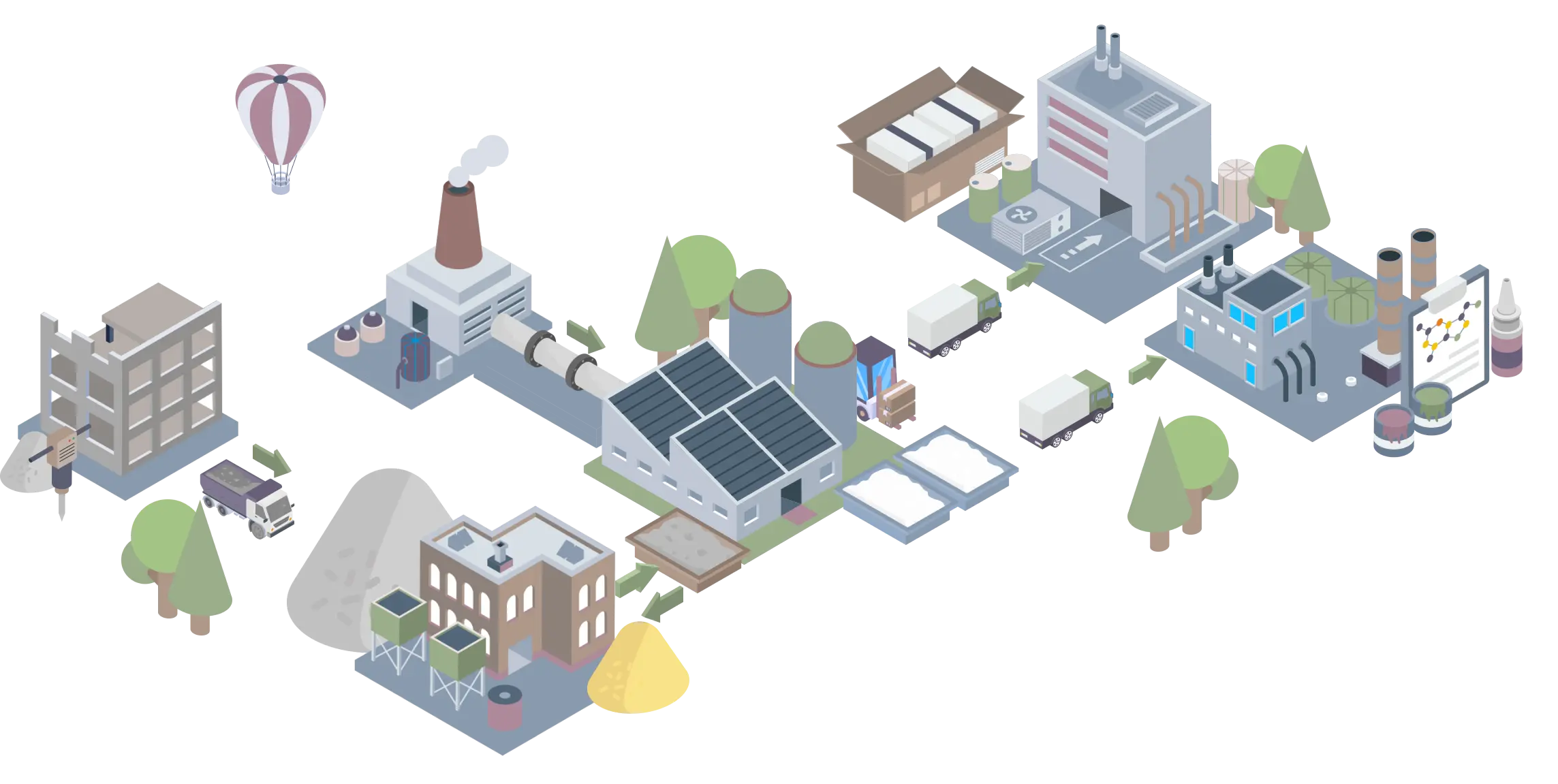

TECHNOLOGY

The solution for high-quality concrete recycling

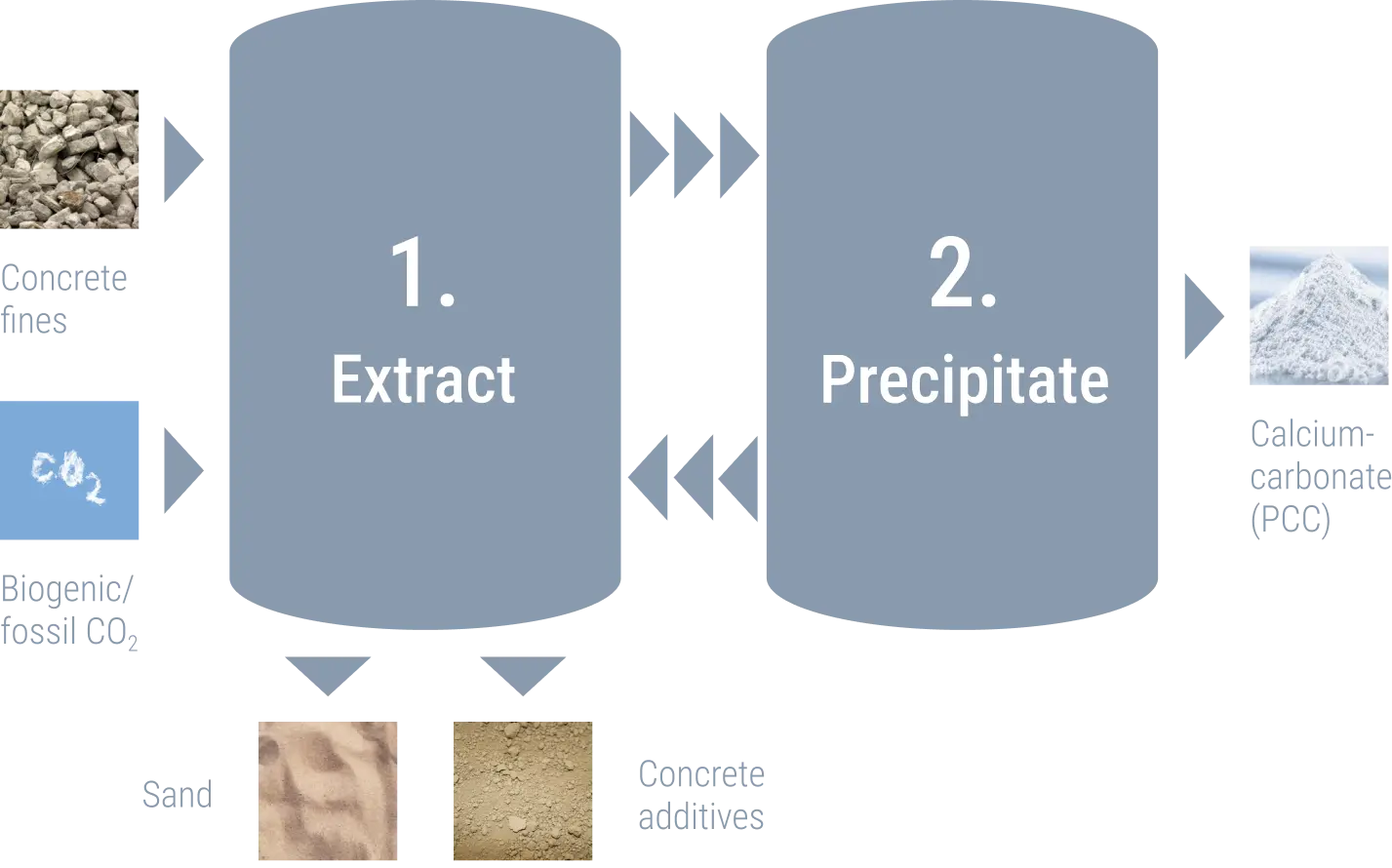

The Rement technology dissolves fine waste concrete from demolition material while storing CO2. In addition to sand, concrete addives and high-purity calcium carbonate are obtained.

DECOMPOSING

Concrete is broken down into its components, which are recycled in the best possible way. Sand is reused in construction, pozzolanic-reactive material is used as a concrete additive and PCC as a filler and pigment.

co2-negative

CO2 is fed into the process and stored in new raw materials. Depending on the utilization of the raw materials, the storage is temporary or permanent. The technology can be operated emission-free. The climate and your CO2 balance benefit.

Genuine Upcycling

The value of the recycled materials exceeds the value of the former fresh concrete - it is therefore genuine upcycling. In addition to earnings from raw material sales, CO2 credits can be offered on the EU ETS or the rapidly growing offset market.

PARTNERS WANTED

Let's collaborate

Plant Users

From C&D waste recycling & cement production

We involve you and your requirements in the development of concrete upcycling systems at an early stage.

.webp)

Material users

From construction chemicals & plastics, paint and paper production

Receive product samples and information to develop circular, climate-friendly products for your portfolio.

.webp)

Decarbonizer

CO2 producers and companies with climate targets

We work with you to develop a new type of value chain in which you benefit from our storage options.

Team Rement

Interested in joining our team?

.webp)

.webp)

.webp)