INPUT

Concrete Waste

Thousands of recycling sites sort and crush billions of tons of demolition concrete each year. We extend their existing value chain by one decisive step - replacing downcycling by upcycling.

We recycle waste concrete and CO2 into high quality, sustainable materials.

To full video

INPUT

Thousands of recycling sites sort and crush billions of tons of demolition concrete each year. We extend their existing value chain by one decisive step - replacing downcycling by upcycling.

INPUT

Concrete causes 8% of global CO2 emissions which cannot be electrified away. And the world won’t stop using concrete. We store purified or diluted CO2 in products.

Request specifications / LCA’s

PRODUCT

We recover sand from the concrete and remove the attached cement stone. The resulting product comes with 100 % recycling share and proven performance in new concrete.

PRODUCT

We win high-value, Precipitated Calcium Carbonate (PCC) from removed cement stone and CO2. Our PCC is pure, white, fine and comes with an excellent Product Carbon Footprint.

We develop concrete upcycling plants that reclaim valuable resources and store carbon at scale. We believe the concrete value chain can only be defossilized and decarbonized by creating attractive circular income streams through outstanding engineering. Speed matters: within our first year, we achieved over 500 hours of stable prototype operation and assembled our pilot plant.

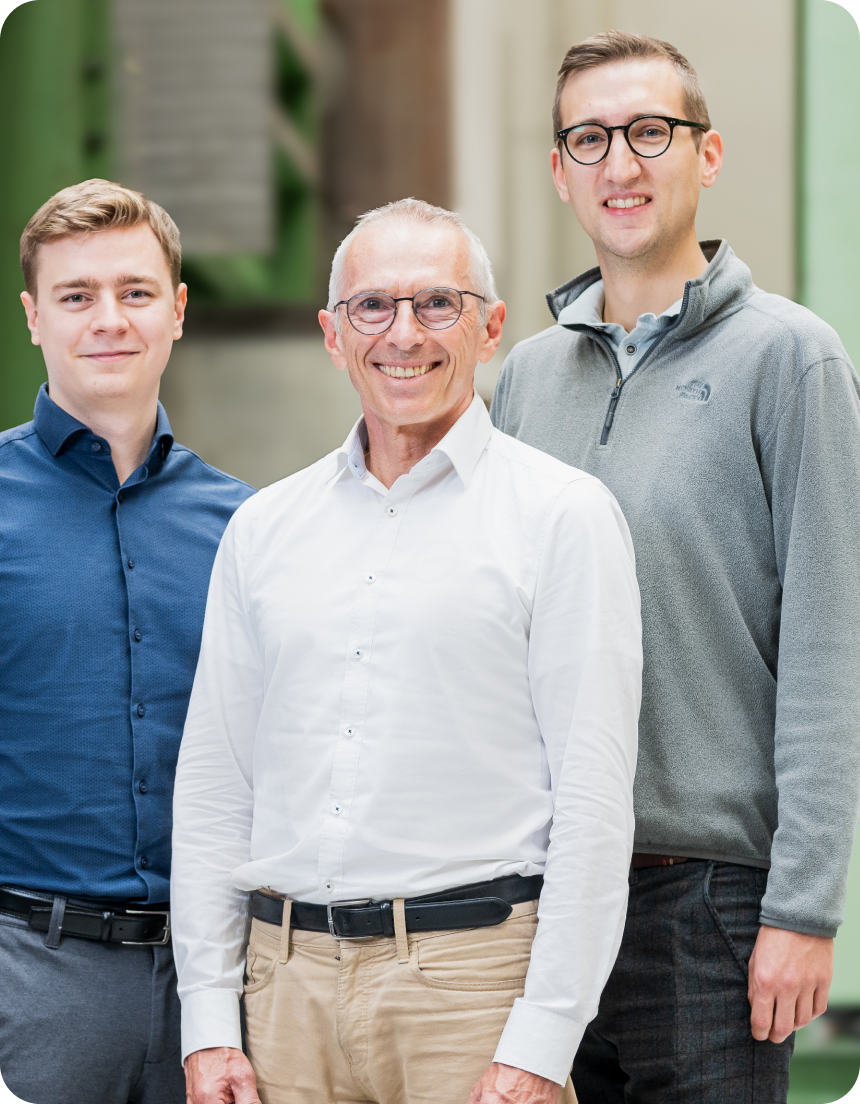

Felix Baur (LinkedIn), Co-CEO and Chief Operating Officer, leads pilot projects, deployments and commissionings. Felix invented our core technology and initiated Rement’s foundation.

Dr. Achim Stammer (LinkedIn), CTO, leads all technological decisions, including IP strategy and industrial scale-up. Achim brings in decades of R&D leadership experience from BASF.

Robert Schleinhege (LinkedIn), Co-CEO and Chief Commercial Officer, oversees financing, partnerships, recruiting, and corporate development. Robert brings in his GTM expertise from startups, corporates and SMEs.

You own the feedstock, we have the technology.

Add an upcycling step to your existing value chain

Extract maximum value out of concrete fines 0/2 and 0/4

Open income streams to new target markets

Contact us

Your products, turned green with Rement materials.

100% Recycling Rates, excellent Product Carbon Footprints

PCC for paint, coatings, sealants, and more

Sand for concrete, precast, construction chemicals, and more

Contact us

All Articles

Sign up for Newsletter

Prof. Frank Dehn Appointed to Advisory Board

February 25, 2026

Deep-Tech in Focus: Robert Schleinhege on Stage with Stefan Quandt and Prof. Jan Hesthaven

February 2, 2026

Philipp Engelkamp Appointed to Advisory Board

January 8, 2026

We recycle waste concrete and CO2 into high quality, sustainable materials.

To full video

INPUT

Thousands of recycling sites sort and crush billions of tons of demolition concrete each year. We extend their existing value chain by one decisive step - replacing downcycling by upcycling.

INPUT

Concrete causes 8% of global CO2 emissions which cannot be electrified away. And the world won’t stop using concrete. We store purified or diluted CO2 in products.

Request specifications / LCA’s

PRODUCT

We recover sand from the concrete and remove the attached cement stone. The resulting product comes with 100 % recycling share and proven performance in new concrete.

PRODUCT

We win high-value, Precipitated Calcium Carbonate (PCC) from removed cement stone and CO2. Our PCC is pure, white, fine and comes with an excellent Product Carbon Footprint.

We develop concrete upcycling plants that reclaim valuable resources and store carbon at scale. We believe the concrete value chain can only be defossilized and decarbonized by creating attractive circular income streams through outstanding engineering. Speed matters: within our first year, we achieved over 500 hours of stable prototype operation and assembled our pilot plant.

Felix Baur (LinkedIn), Co-CEO and Chief Operating Officer, leads pilot projects, deployments and commissionings. Felix invented our core technology and initiated Rement’s foundation.

Dr. Achim Stammer (LinkedIn), CTO, leads all technological decisions, including IP strategy and industrial scale-up. Achim brings in decades of R&D leadership experience from BASF.

Robert Schleinhege (LinkedIn), Co-CEO and Chief Commercial Officer, oversees financing, partnerships, recruiting, and corporate development. Robert brings in his GTM expertise from startups, corporates and SMEs.

You own the feedstock, we have the technology.

Add an upcycling step to your existing value chain

Extract maximum value out of concrete fines 0/2 and 0/4

Open income streams to new target markets

Contact us

Your products, turned green with Rement materials.

100 % Recycling Rates, excellent Product Carbon Footprints

PCC for paint, coatings, sealants, and more

Sand for concrete, precast, construction chemicals, and more

Contact us

All Articles

Sign up for Newsletter

Prof. Frank Dehn Appointed to Advisory Board

February 25, 2026

Deep-Tech in Focus: Robert Schleinhege on Stage with Stefan Quandt and Prof. Jan Hesthaven

February 2, 2026

Philipp Engelkamp Appointed to Advisory Board

January 8, 2026

We recycle waste concrete and CO2 into high quality, sustainable materials.

To full video

INPUT

Thousands of recycling sites sort and crush billions of tons of demolition concrete each year. We extend their existing value chain by one decisive step - replacing downcycling by upcycling.

INPUT

Concrete causes 8% of global CO2 emissions which cannot be electrified away. And the world won’t stop using concrete. We store purified or diluted CO2 in products.

Request specifications / LCA’s

PRODUCT

We recover sand from the concrete and remove the attached cement stone. The resulting product comes with 100 % recycling share and proven performance in new concrete.

PRODUCT

We win high-value, Precipitated Calcium Carbonate (PCC) from removed cement stone and CO2. Our PCC is pure, white, fine and comes with an excellent Product Carbon Footprint.

We develop concrete upcycling plants that reclaim valuable resources and store carbon at scale. We believe the concrete value chain can only be defossilized and decarbonized by creating attractive circular income streams through outstanding engineering. Speed matters: within our first year, we achieved over 500 hours of stable prototype operation and assembled our pilot plant.

Felix Baur (LinkedIn), Co-CEO and Chief Operating Officer, leads pilot projects, deployments and commissionings. Felix invented our core technology and initiated Rement’s foundation.

Dr. Achim Stammer (LinkedIn), CTO, leads all technological decisions, including IP strategy and industrial scale-up. Achim brings in decades of R&D leadership experience from BASF.

Robert Schleinhege (LinkedIn), Co-CEO and Chief Commercial Officer, oversees financing, partnerships, recruiting, and corporate development. Robert brings in his GTM expertise from startups, corporates and SMEs.

You own the feedstock, we have the technology.

Add an upcycling step to your existing value chain

Extract maximum value out of concrete fines 0/2 and 0/4

Open income streams to new target markets

Contact us

Your products, turned green with Rement materials.

100% recycling share, excellent Product Carbon Footprints

PCC for paint, coatings, sealants, and more

Sand for concrete, precast, construction chemicals, and more

Contact us

All Articles

Sign up for Newsletter

Prof. Frank Dehn Appointed to Advisory Board

February 25, 2026

Deep-Tech in Focus: Robert Schleinhege on Stage with Stefan Quandt and Prof. Jan Hesthaven

February 2, 2026

Philipp Engelkamp Appointed to Advisory Board

January 8, 2026

We recycle waste concrete and CO2 into high quality, sustainable materials.

To full video

INPUT

Thousands of recycling sites sort and crush billions of tons of demolition concrete each year. We extend their existing value chain by one decisive step - replacing downcycling by upcycling.

INPUT

Concrete causes 8% of global CO2 emissions which cannot be electrified away. And the world won’t stop using concrete. We store purified or diluted CO2 in products.

Request specifications / LCA’s

PRODUCT

We recover sand from the concrete and remove the attached cement stone. The resulting product comes with 100 % recycling share and proven performance in new concrete.

PRODUCT

We win high-value, Precipitated Calcium Carbonate (PCC) from removed cement stone and CO2. Our PCC is pure, white, fine and comes with an excellent Product Carbon Footprint.

We develop concrete upcycling plants that reclaim valuable resources and store carbon at scale. We believe the concrete value chain can only be defossilized and decarbonized by creating attractive circular income streams through outstanding engineering. Speed matters: within our first year, we achieved over 500 hours of stable prototype operation and assembled our pilot plant.

Felix Baur (LinkedIn), Co-CEO and Chief Operating Officer, leads pilot projects, deployments and commissionings. Felix invented our core technology and initiated Rement’s foundation.

Dr. Achim Stammer (LinkedIn), CTO, leads all technological decisions, including IP strategy and industrial scale-up. Achim brings in decades of R&D leadership experience from BASF.

Robert Schleinhege (LinkedIn), Co-CEO and Chief Commercial Officer, oversees financing, partnerships, recruiting, and corporate development. Robert brings in his GTM expertise from startups, corporates and SMEs.

You own the feedstock, we have the technology.

Add an upcycling step to your existing value chain

Extract maximum value out of concrete fines 0/2 and 0/4

Open income streams to new target markets

Contact us

Your products, turned green with Rement materials.

100% recycling share, excellent Product Carbon Footprints

PCC for paint, coatings, sealants, and more

Sand for concrete, precast, construction chemicals, and more

Contact us

All Articles

Sign up for Newsletter

Prof. Frank Dehn Appointed to Advisory Board

February 25, 2026

Deep-Tech in Focus: Robert Schleinhege on Stage with Stefan Quandt and Prof. Jan Hesthaven

February 2, 2026

Philipp Engelkamp Appointed to Advisory Board

January 8, 2026